Vapor Deposition The main Thermal CVD technology involves adding gases to the pressurized reactor at high temperature of about 1,000℃ where thin film is synthesized onto substrates.

- Size (mm): 2300(W) x 1770(H) x 750(D)

- Up to 10 gases 3 MO sources for gas-phase synthesis.

- Motor-controlled movable heater for fast heating cooling (patented).

- Fully computer-controlled programmable recipes.

- TCVD100 platform: Proven performance for ~100 systems for more than 5 years.

- Invited training for full sample preparation processes from synthesis, etching, transfer.

- Supply of high-quality source materials.

- 1 year warranty included (2 year extended warranty available)

- CVD chambers connected to a Glove Box. Free from air exposure.

- *Price will be determined after consultation.

- (Different customization from the standard parts will affect the overall price.)

You can see the image to the left or right by turning the equipment

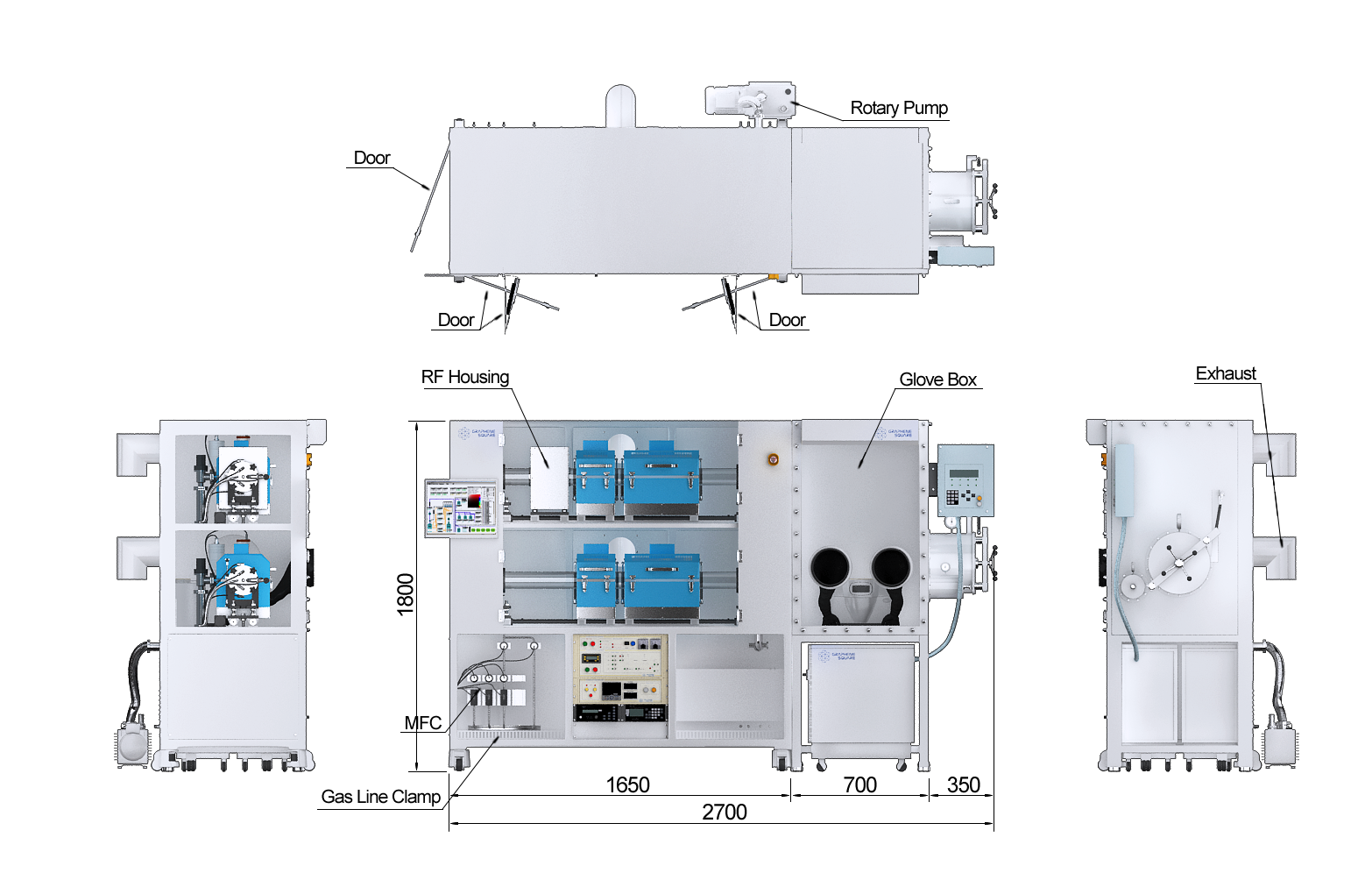

Glove Box System A Bi-level Dual CVD Chamber system with a unique design. Capable of specialized and diverse research. Glove Box included.

-

-

Specifications

Thermal CVD Auto Operation system - 2channel operation

Both End chamber(Stainess) - All parts cooling by water

Glove box unit (Sample Auto-loading and Anti-contamination)

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

340liter/min Oil rotary pump

Pneumatic On/off valve with Auto pressure control Throttle valve

Programmable Temperature controller

High Temperature Furnace(Max1200℃)

Rapid Cooling system by furnace moving

Atmospheric and Vacuum Processing

Anti-contamination system by inner tube

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

On-site install and tranning

System Program (Auto processing system)

Safety Cover (Connected exhaust system)

High Vacuum processing (Pump/Gauge/valve unit)

RF plasma (ICP type)

-

Options

Max temp 1500℃ Furnace by SIC source

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600℃

MFC(Mass flow controller) addtion total 12channel

Dry vacuum pump ( Scroll / booster / industry)

Safety interlock system(Water / Air/gas leak)

Tungsten filament gas source cracking

Additional Furnace for source evaporation

High Vacuum processing option (Pump/Gauge/valve unit)

Source delivery system ( Bubbler / Gas / Solid )

System Utility ( Chiller / scrubber / gas cabinet )

System Co-operation( 2system simultaneous operation)

-

Consumable Parts

K-type Thermocouple (Option : R-type)

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

-

Specifications

-

Facility Requirements

Electrical power 220VAC 1ph 75A Compressed air 0.5~0.6Mpa Compressed air input size 6 mm one touch fitting Cooling water in/out 3/8" lok fitting cooling water flow Air temp 5~7liter/min cooling water pressure 0.1~0.2Mpa Safety exhaust size 6 mm one touch tube Gas input pressure 40ps Gas port 4ch standard (Option 2ch Expansion) Gas port size 1/4"lok fitting Pump exhaust NW25 Rotary pump capacity 340liter/min Vent 1/4"lok fitting -

Layout

-

Standard Warranty

Each system is delivered with a limited warranty that covers parts, excluding consumable and wearable parts such as quartz ware and O-rings, for one (1) year from the date of commissioning of the system. Any parts confirmed to be defective will be sent to customer for replacement during the warranty period. *Note: Any unauthorized modification of the system will result in the voiding of warranty.

-

Delivery Time & Shipping Policy

The delivery time is estimated to be 8-12 weeks upon receipt of order. Graphene Square Inc. ships each system to the customer site by Incoterms CIP (Carriage & Insurance Paid) air freight direct from its factory in Korea.

-

Equipment Purchasing Process

-

1

Request Quote

-

2

Confirm Quote Details with Purchase Order

-

3

Invoice / Payment

Send Invoice and Payment information

-

4

System Production Initiated with Down Payment

Training program offered

-

5

Equipment Operation Test / Export packaging & shipment

Upon completion of system production, factory operation test performed.

-

6

Express Air Shipment & Delivery

Estimated delivery

– 4 business days

-

1

-

FAQ

Construction...